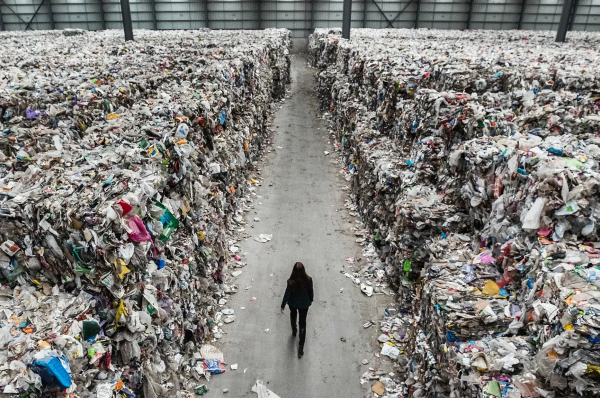

The global plastic crisis demands innovative solutions to tackle waste effectively. AVRO, with over 22 years of expertise, is redefining the future of plastic recycling by embracing advanced technologies and sustainable practices. With plans to double its recycling capacity to 12,000 MTPA by FY25, AVRO is setting a benchmark for the industry, transforming challenges into opportunities and waste into wealth.

Revolutionizing Recycling Through Technology

- Advanced Sorting Systems

At the heart of AVRO’s recycling operations is its investment in cutting-edge sorting technology. Using automated systems, plastics are accurately categorized based on type, grade, and usability. This precision ensures higher-quality recycled materials and reduces contamination. - Chemical Recycling Techniques

Beyond traditional mechanical recycling, AVRO is exploring chemical recycling methods. This innovation breaks down plastic waste into its molecular components, allowing even heavily contaminated plastics to be transformed into high-grade raw materials. - Energy-Efficient Processes

AVRO’s recycling plants are designed to minimize energy consumption while maximizing output. By integrating renewable energy sources and optimizing production workflows, the company reduces its carbon footprint. - Material Innovation

AVRO’s R&D team continually works on enhancing the properties of recycled plastics. From improving strength and durability to creating materials with better weather resistance, these innovations enable the production of superior furniture products.

Scaling Up for a Sustainable Future

- Doubling Recycling Capacity

By FY25, AVRO aims to recycle 12,000 MTPA of plastic waste, doubling its current capacity. This expansion is not just about increasing output but also about creating a scalable model that can be replicated globally. - Expanding Product Lines

The company’s innovation doesn’t stop at recycling. AVRO is leveraging recycled materials to develop new product lines, ensuring versatility and sustainability go hand in hand. - Partnerships for Growth

AVRO is collaborating with waste management organizations, research institutions, and technology providers to stay ahead of the curve. These partnerships enable the company to access the latest advancements and amplify its impact.

Driving a Circular Economy

AVRO’s innovations are not limited to recycling; they embody the principles of a circular economy. By transforming waste into durable and attractive furniture, AVRO closes the loop, creating a sustainable lifecycle for plastic products.

Consumer Empowerment

AVRO empowers consumers to be part of this revolution by offering stylish, affordable, and eco-friendly furniture. Each purchase contributes to reducing plastic pollution and promoting sustainable practices.

Challenges and AVRO’s Solutions

While the path to innovation is not without obstacles, AVRO is equipped to overcome them:

- Plastic Diversity: AVRO’s advanced sorting and processing capabilities address the challenges of handling different plastic types.

- Consumer Awareness: The company runs campaigns to educate consumers about the importance of recycling and eco-friendly choices.

- Scaling Infrastructure: Through strategic investments, AVRO ensures its facilities are prepared for future growth.

Conclusion

AVRO’s approach to plastic recycling is not just about solving today’s problems—it’s about creating a sustainable tomorrow. By harnessing innovation, expanding capabilities, and promoting a circular economy, AVRO is redefining the possibilities of plastic recycling.

The future is clear: with companies like AVRO leading the way, we can turn plastic waste into a resource, transform industries, and build a cleaner, greener planet. Join AVRO on this journey to a sustainable future.

4o